Elio Motors Momentum v93

If you’ve been following Elio Motors for any length of time, you probably know the importance of the literal “driver” of our project: our engine. In the beginning stages of the project, it became evident that the best way to achieve our goals was to design and build our own engine. Today, we will take a look at some improvements our engineering team has made to the Elio Motors engine.

Our engineering team constantly looks at our engine and finds ways and areas in which we can make improvements. As we conduct various simulations and design studies, we identify potential enhancements in areas such as fuel consumption, friction, gearing, and weight.

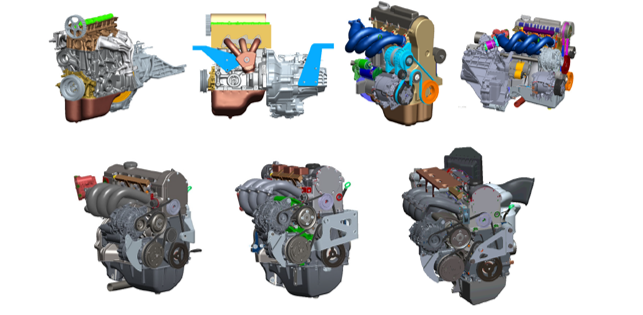

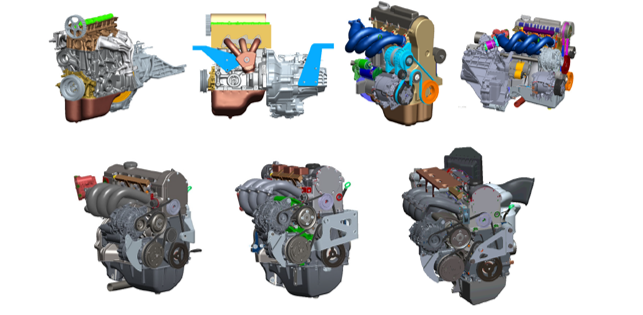

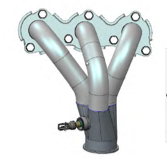

Here is a photo to give you an idea how our engine has evolved over time:

We will look at three areas in which our team has found improvements to our engine: the intake manifold, the exhaust manifold, and the front engine accessory drive (FEAD.)

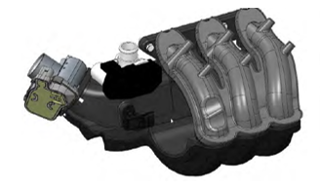

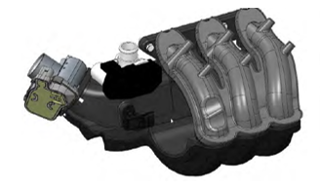

Intake Manifold

To develop the best possible engine, we must first determine the best possible materials to use. The intake manifold of our engine has changed over time as we endeavored to identify the right material. Through countless hours of testing, our team narrowed down the possible materials to steel, casting, and composites. Through this analytical testing we were able to conclude that a composite is the best choice because of its adaptiveness to various ranges of temperature, weight, and manufacturability.

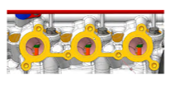

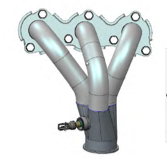

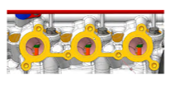

Exhaust Manifold

Similar to the intake manifold, our engine’s exhaust manifold endured a battery of tests to determine the correct material. Running CAE tests using both a casting and a steel tube design, we concluded that while a steel design is more expensive, it is the correct choice for our engine. The steel tube design is preferable because of its lower weight, better durability, and its tuning of the motor and effectiveness in managing the gases. Additionally, the placement of the tubes have been precisely calculated to ensure that our fuel usage is maximized.

Front Engine Accessory Drive

There have been several significant changes to the placement of components on the front of the engine. The air conditioner has shifted to the lower rear portion of the engine to control noise vibration and improve the cabin experience. The 120 amp alternator is positioned at the top of the motor to offer the most effective means of balancing the motor by providing the proper amount of tension on the belt. The size of the bracket has been significantly reduced to reduce weight and improve manufacturability. We have placed a belt tensioner onto the interface, making it easier to change the belt. Also, the water pump has been placed on the front side of the motor. The totality of these changes to the FEAD makes our engine much lighter, more efficient, and easier to manufacture.

Our motor is made up of over 200 components, not including fasteners, and weighs approximately 181 pounds. Each component and pound of our engine has been meticulously probed and analyzed for potential improvements. The improvements to the exhaust manifold, intake manifold, and FEAD are just a couple of examples of our commitment to building the best possible vehicle.

*MSRP for non-refundable reservations only and applies only until non-refundable and refundable reservations total 65,000. Total current reservations can be seen at: eliomotors.com. MSRP excludes destination/delivery charges, taxes, title, registration, and options/installation.

Certain statements in this email including, but not limited to, statements related to anticipated commencement of commercial production, targeted pricing and performance goals, and statements that otherwise relate to future periods are forward-looking statements. These statements involve risks and uncertainties, which are described in more detail in the Company’s periodic reports filed with the SEC, specifically the most recent reports which identify important risk factors that could cause actual results to differ from those contained in the forward-looking statements. Forward-looking statements are made and based on information available to the Company on the date of this email. Elio Motors assumes no obligation to update the information in this email.

If you’ve been following Elio Motors for any length of time, you probably know the importance of the literal “driver” of our project: our engine. In the beginning stages of the project, it became evident that the best way to achieve our goals was to design and build our own engine. Today, we will take a look at some improvements our engineering team has made to the Elio Motors engine.

Our engineering team constantly looks at our engine and finds ways and areas in which we can make improvements. As we conduct various simulations and design studies, we identify potential enhancements in areas such as fuel consumption, friction, gearing, and weight.

Here is a photo to give you an idea how our engine has evolved over time:

We will look at three areas in which our team has found improvements to our engine: the intake manifold, the exhaust manifold, and the front engine accessory drive (FEAD.)

Intake Manifold

To develop the best possible engine, we must first determine the best possible materials to use. The intake manifold of our engine has changed over time as we endeavored to identify the right material. Through countless hours of testing, our team narrowed down the possible materials to steel, casting, and composites. Through this analytical testing we were able to conclude that a composite is the best choice because of its adaptiveness to various ranges of temperature, weight, and manufacturability.

Exhaust Manifold

Similar to the intake manifold, our engine’s exhaust manifold endured a battery of tests to determine the correct material. Running CAE tests using both a casting and a steel tube design, we concluded that while a steel design is more expensive, it is the correct choice for our engine. The steel tube design is preferable because of its lower weight, better durability, and its tuning of the motor and effectiveness in managing the gases. Additionally, the placement of the tubes have been precisely calculated to ensure that our fuel usage is maximized.

Front Engine Accessory Drive

There have been several significant changes to the placement of components on the front of the engine. The air conditioner has shifted to the lower rear portion of the engine to control noise vibration and improve the cabin experience. The 120 amp alternator is positioned at the top of the motor to offer the most effective means of balancing the motor by providing the proper amount of tension on the belt. The size of the bracket has been significantly reduced to reduce weight and improve manufacturability. We have placed a belt tensioner onto the interface, making it easier to change the belt. Also, the water pump has been placed on the front side of the motor. The totality of these changes to the FEAD makes our engine much lighter, more efficient, and easier to manufacture.

Our motor is made up of over 200 components, not including fasteners, and weighs approximately 181 pounds. Each component and pound of our engine has been meticulously probed and analyzed for potential improvements. The improvements to the exhaust manifold, intake manifold, and FEAD are just a couple of examples of our commitment to building the best possible vehicle.

*MSRP for non-refundable reservations only and applies only until non-refundable and refundable reservations total 65,000. Total current reservations can be seen at: eliomotors.com. MSRP excludes destination/delivery charges, taxes, title, registration, and options/installation.

Certain statements in this email including, but not limited to, statements related to anticipated commencement of commercial production, targeted pricing and performance goals, and statements that otherwise relate to future periods are forward-looking statements. These statements involve risks and uncertainties, which are described in more detail in the Company’s periodic reports filed with the SEC, specifically the most recent reports which identify important risk factors that could cause actual results to differ from those contained in the forward-looking statements. Forward-looking statements are made and based on information available to the Company on the date of this email. Elio Motors assumes no obligation to update the information in this email.