Ekh

Elio Addict

Elio Motors Tech Talk v38

View this email in your browser

Why We Went with a New Engine Design: Finding the Balance Between Fuel Efficiency, Power

The Elio Motors project has had three main goals for the powertrain team:

1. Up to 84 MPG for the highway drive cycle

2. The powertrain needs to be low cost

3. The powertrain needs to be comparable to current automotive quality standards.

Looking at these independently, each are not difficult to achieve, but together this is quite the challenge.

The original engine concept was to take the Geo Metro engine and create a template for the Elio engine. Overall it is compact, perceived to be efficient, has the correct power requirements, and is relatively inexpensive to produce. As the team began to dive into some of the details and changes to meet the desired Elio targets, one thing became apparent: the Geo Metro engine would not meet the fuel efficiency targets to enable the vehicle fuel economy goal of 84 MPG highway.

After running computer simulations, it was apparent that a new engine design was needed to work with the Elio vehicle to achieve this goal and still maintain a top speed of more than 100 MPH with a goal of 0-to-60 MPH in less than 10 seconds.

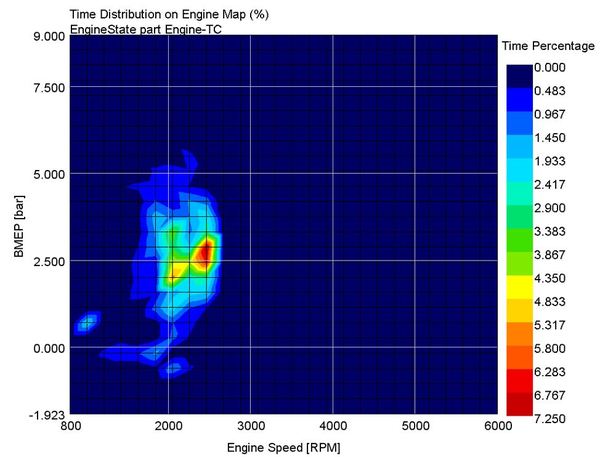

Figure 1: Geo Metro operating load on the highway drive cycle in an Elio.

Since the Elio is considerably lighter than anything else on the market today, a suitable existing engine was not available. This included the Geo Metro engine since it was optimized for running at the higher load used in a heavier and larger vehicle. The conclusion was clear – to meet the vehicle performance, economy, and cost objectives, a new engine would be necessary.

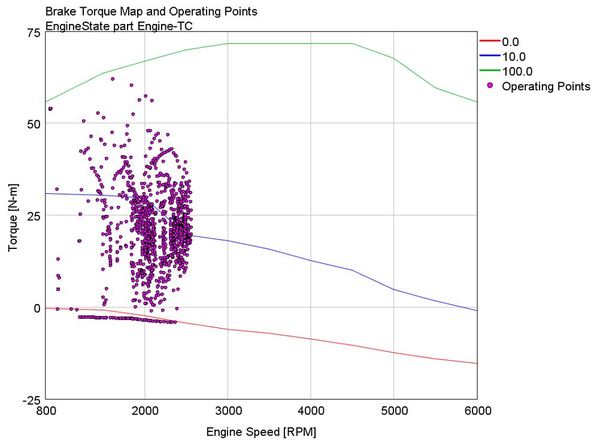

Figure 2: Geo Metro operating torque on the highway drive cycle in an Elio.

With the decision to design a new engine for the Elio, the program focused on determining the technical features needed to achieve the targets. The team looked at the Geo Metro design to see if modernizing the 30-year-old strategy would make it more efficient. The outcome was to maintain the three cylinder architecture, but update the cylinder block, cylinder heads, CAM cover, front cover, oil pan, crankshaft, camshaft, valvetrain, pistons, connecting rods, bearings and water pump to Elio specifically designed components. This allowed the engine development team the flexibility to keep the design simple, efficient and easy to manufacture while enabling all of the major fuel economy related attributes – combustion system, friction and pumping energy – to be enhanced. Many parts were identified as cost and risk reductions to be sourced as currently produced off-the-shelf components. All of the sensors, alternator, A/C compressor, oil filter, air filter, electronic throttle body and the engine control system are all currently produced and available at your local service center.

Over the next couple of weeks, we will share some additional details about the Engine Control Unit (ECU), show nearly all of the components that have been machined to date and finally show the prototype Elio engine fully assembled. In doing so, the powertrain Tech Talk series will answer many of the questions you, our Elio fans and supporters, have been anxiously anticipating.

Copyright © 2014 Elio Motors, All rights reserved.

View this email in your browser

Why We Went with a New Engine Design: Finding the Balance Between Fuel Efficiency, Power

The Elio Motors project has had three main goals for the powertrain team:

1. Up to 84 MPG for the highway drive cycle

2. The powertrain needs to be low cost

3. The powertrain needs to be comparable to current automotive quality standards.

Looking at these independently, each are not difficult to achieve, but together this is quite the challenge.

The original engine concept was to take the Geo Metro engine and create a template for the Elio engine. Overall it is compact, perceived to be efficient, has the correct power requirements, and is relatively inexpensive to produce. As the team began to dive into some of the details and changes to meet the desired Elio targets, one thing became apparent: the Geo Metro engine would not meet the fuel efficiency targets to enable the vehicle fuel economy goal of 84 MPG highway.

After running computer simulations, it was apparent that a new engine design was needed to work with the Elio vehicle to achieve this goal and still maintain a top speed of more than 100 MPH with a goal of 0-to-60 MPH in less than 10 seconds.

Figure 1: Geo Metro operating load on the highway drive cycle in an Elio.

Since the Elio is considerably lighter than anything else on the market today, a suitable existing engine was not available. This included the Geo Metro engine since it was optimized for running at the higher load used in a heavier and larger vehicle. The conclusion was clear – to meet the vehicle performance, economy, and cost objectives, a new engine would be necessary.

Figure 2: Geo Metro operating torque on the highway drive cycle in an Elio.

With the decision to design a new engine for the Elio, the program focused on determining the technical features needed to achieve the targets. The team looked at the Geo Metro design to see if modernizing the 30-year-old strategy would make it more efficient. The outcome was to maintain the three cylinder architecture, but update the cylinder block, cylinder heads, CAM cover, front cover, oil pan, crankshaft, camshaft, valvetrain, pistons, connecting rods, bearings and water pump to Elio specifically designed components. This allowed the engine development team the flexibility to keep the design simple, efficient and easy to manufacture while enabling all of the major fuel economy related attributes – combustion system, friction and pumping energy – to be enhanced. Many parts were identified as cost and risk reductions to be sourced as currently produced off-the-shelf components. All of the sensors, alternator, A/C compressor, oil filter, air filter, electronic throttle body and the engine control system are all currently produced and available at your local service center.

Over the next couple of weeks, we will share some additional details about the Engine Control Unit (ECU), show nearly all of the components that have been machined to date and finally show the prototype Elio engine fully assembled. In doing so, the powertrain Tech Talk series will answer many of the questions you, our Elio fans and supporters, have been anxiously anticipating.

Copyright © 2014 Elio Motors, All rights reserved.

Attachments

-

83468eef-7e35-4e13-897e-736414932a0d.jpg15.2 KB · Views: 362

83468eef-7e35-4e13-897e-736414932a0d.jpg15.2 KB · Views: 362 -

06b5288a-73ab-4d78-a4c8-766d74eecec2.jpg43.4 KB · Views: 355

06b5288a-73ab-4d78-a4c8-766d74eecec2.jpg43.4 KB · Views: 355 -

c45fafa9-26d2-46d7-b499-92826319ed74.jpg36.2 KB · Views: 336

c45fafa9-26d2-46d7-b499-92826319ed74.jpg36.2 KB · Views: 336 -

8e757105-a60e-4b45-972d-2d7cf95640cd.jpg10.1 KB · Views: 357

8e757105-a60e-4b45-972d-2d7cf95640cd.jpg10.1 KB · Views: 357 -

23e0b01f-8f1b-46ca-b65c-9b12f2c1b348.jpg15.3 KB · Views: 0

Last edited by a moderator: