zelio

Elio Addict

Elio Motors Tech Talk v31

View this email in your browser

Elio 3 Cylinder Cooling System

One of the key areas of focus for the engine design is the cooling system. This system includes the water jacket around the cylinder chambers and the cylinder head, the cylinder head gasket and the water pump. Significant analysis and design has gone into the Elio engine.

Water Jacket

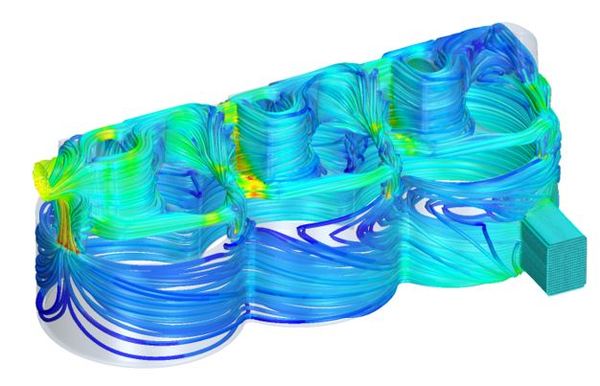

When designing the water jacket, the focus was to maximize the cooling potential in terms of maximum flow velocity, maximum velocity distribution, minimum volume, and minimum metal temperature. The design was then analyzed using modern Computational Fluid Dynamic (CFD) software to optimize the prototype layout.

Image 1: CFD of the Elio Crankcase Water Jacket

The cylinder head portion of the water jacket was designed with the intent of maximum combustion chamber cooling; reducing the required octane content in the fuel used which in turn allowed for higher compression ratios. The volume was kept to a minimum to keep flow velocity as high as possible. A connecting bridge was also added along the “spine” of the water jacket which had the benefits of increasing cross-cylinder flow velocity as well as eliminating air pockets that would accumulate between the cylinders. Detail was also taken to extend and loop the water passages around important cylinder head features like the intake port, the exhaust port and the spark plug, thus maximizing the cooling area.

Cylinder Head Gasket

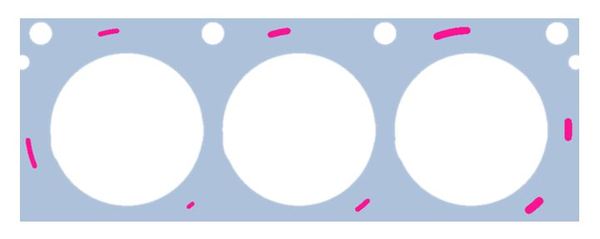

Size, shape, and the location of the orifices in the gasket were tuned to optimize flow from the cylinder into the head sections of the water jacket. The orifices around cylinder one were made larger to encourage additional flow into the head at cylinder one, with smaller orifices around cylinders two and three to keep flow velocity high and uniform. The design allows most of the water to come up at cylinder one, then travel across the top of the cylinders to the outlet, instead of flowing the water up and over one cylinder at a time.

Image 2: Elio Cylinder Head Gasket

Water Pump

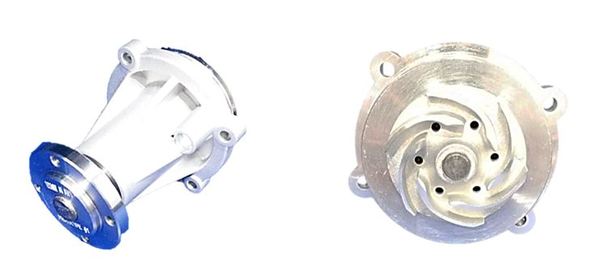

The water pump was designed to be more efficient by using curved vane impellers, and to operate at a lower flow rate, resulting in a water pump which is slower with reduced parasitic properties. The water pump is mounted off to the bulkhead side, with the water jacket intake coming in on the side of the engine instead of on the front cover. This was done to keep the water from the water pump separate from the oil in the wet front cover in the event of a water pump failure. Pressure relief holes are drilled into the impeller base to relieve the negative back pressure between the impeller and seal caused by the impeller rotation. This preserves both seal integrity and flow uniformity. A small chamfer is added on the leading edge of the impeller blades to reduce flow separation, therefore reducing cavitation.

Image 3: Elio Water Pump

With all of the design and analysis that has gone into the cooling system, the Elio engine will remain at optimal operational temperature with a minimal effort.

Copyright © 2014 Elio Motors, All rights reserved.

You signed up to receive updates from Elio Motors where you filled out a form including your name and email address!

Our mailing address is:

Elio Motors

2942 North 24th Street

Suite 114-700

Phoenix, AZ 85016

Add us to your address book

View this email in your browser

Elio 3 Cylinder Cooling System

One of the key areas of focus for the engine design is the cooling system. This system includes the water jacket around the cylinder chambers and the cylinder head, the cylinder head gasket and the water pump. Significant analysis and design has gone into the Elio engine.

Water Jacket

When designing the water jacket, the focus was to maximize the cooling potential in terms of maximum flow velocity, maximum velocity distribution, minimum volume, and minimum metal temperature. The design was then analyzed using modern Computational Fluid Dynamic (CFD) software to optimize the prototype layout.

Image 1: CFD of the Elio Crankcase Water Jacket

The cylinder head portion of the water jacket was designed with the intent of maximum combustion chamber cooling; reducing the required octane content in the fuel used which in turn allowed for higher compression ratios. The volume was kept to a minimum to keep flow velocity as high as possible. A connecting bridge was also added along the “spine” of the water jacket which had the benefits of increasing cross-cylinder flow velocity as well as eliminating air pockets that would accumulate between the cylinders. Detail was also taken to extend and loop the water passages around important cylinder head features like the intake port, the exhaust port and the spark plug, thus maximizing the cooling area.

Cylinder Head Gasket

Size, shape, and the location of the orifices in the gasket were tuned to optimize flow from the cylinder into the head sections of the water jacket. The orifices around cylinder one were made larger to encourage additional flow into the head at cylinder one, with smaller orifices around cylinders two and three to keep flow velocity high and uniform. The design allows most of the water to come up at cylinder one, then travel across the top of the cylinders to the outlet, instead of flowing the water up and over one cylinder at a time.

Image 2: Elio Cylinder Head Gasket

Water Pump

The water pump was designed to be more efficient by using curved vane impellers, and to operate at a lower flow rate, resulting in a water pump which is slower with reduced parasitic properties. The water pump is mounted off to the bulkhead side, with the water jacket intake coming in on the side of the engine instead of on the front cover. This was done to keep the water from the water pump separate from the oil in the wet front cover in the event of a water pump failure. Pressure relief holes are drilled into the impeller base to relieve the negative back pressure between the impeller and seal caused by the impeller rotation. This preserves both seal integrity and flow uniformity. A small chamfer is added on the leading edge of the impeller blades to reduce flow separation, therefore reducing cavitation.

Image 3: Elio Water Pump

With all of the design and analysis that has gone into the cooling system, the Elio engine will remain at optimal operational temperature with a minimal effort.

Copyright © 2014 Elio Motors, All rights reserved.

You signed up to receive updates from Elio Motors where you filled out a form including your name and email address!

Our mailing address is:

Elio Motors

2942 North 24th Street

Suite 114-700

Phoenix, AZ 85016

Add us to your address book